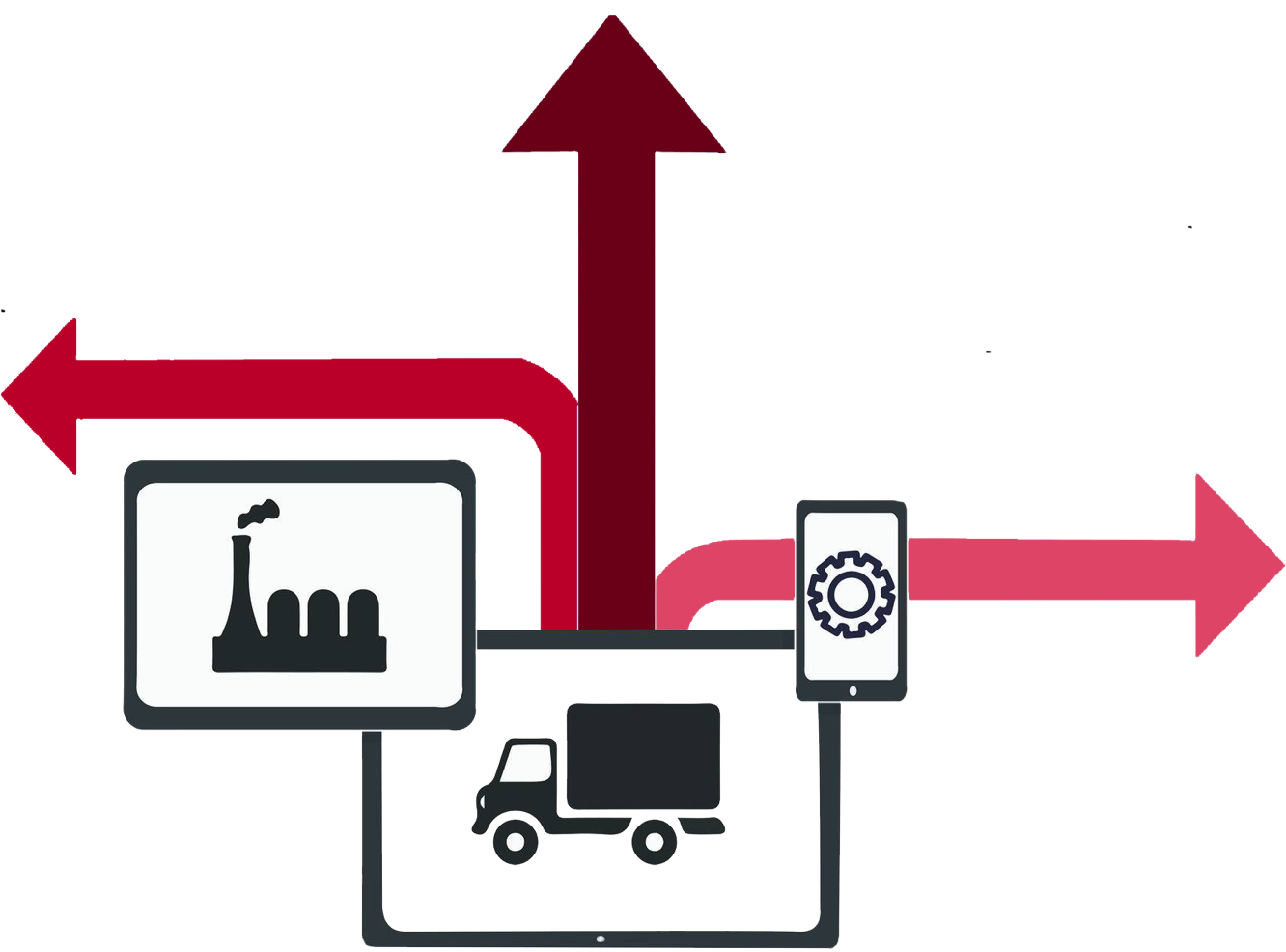

THE INDUSTRIAL INTERNET OF THINGS (IIOT)

The return on IIoT information systems is THE information

Blackhawk Systems was created to enable both the suppliers and the OEM communities to reduce costs while increasing quality, improving customer service, and increasing real-time visibility.

Over the past 20 years, Blackhawk Systems has been helping its clients become world class contenders in the repetitive manufacturing industry. In that time, five of the plants that have implemented our solution have made it to Industry Week’s “Top 10 Manufacturing Plants”.

We provide fully integrated, real-time, paperless (scancentric) shop floor automation solutions to repetitive parts suppliers. These solutions integrate seamlessly into current systems creating an interrelated scheme capable of a multitude of defined tasks.

Blackhawk Systems Provides:

- Lean Inventory through scan-centric inventory movement with FIFO enforcement

- Lean Labor through point of occurrence recording

- Labeling Accuracy through on-demand, line-side label generation

- Master label accuracy through line side “build-a-pallet” simple container label scanning

- Error Proofing Integration of ERP/EDI business rules

- 100% Containment – non-conforming product cannot be shipped

- Manufacturing Process History – every process environmental can be recorded

- Lot Tracking – from receiving to shipping

- Receiving Accuracy – scan-centric and lot tracking

- Shipping Accuracy – scan-centric container label conformance enforcement

- Real time visibility of the entire production floor