Best practices for part labeling and tracking

As we are becoming better known in the sequencing industry, we are being asked about some fundamental best practices that are built into our shopfloor 4.0 architecture.

The latest one that came across my desk deals with the “best” design for part serialization/tracking. Because of the quality conformance requirements needed with manufacturing in sequence, this level of part labeling/tracking is a standard within our business solutions (Shopfloor 4.0)

The part label (standard within all Blackhawk ShopFloor 4.0)

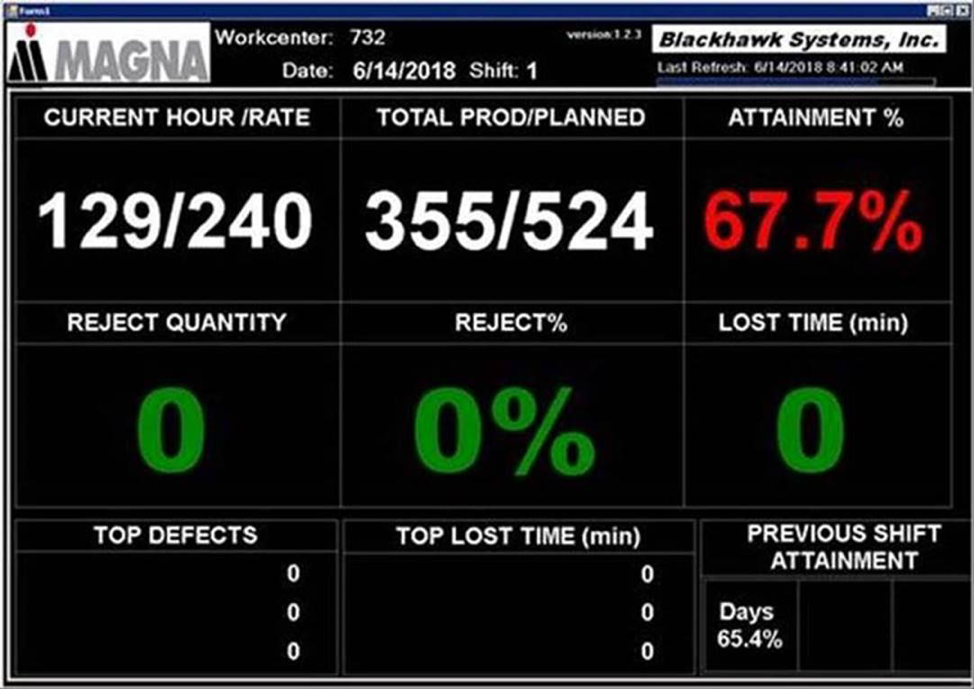

Within the Blackhawk architecture, we strongly suggest that the label be printed through a machine interface (PLC). This enables a high degree of error-proofing the label to the fixture, to the part, as well as the accurate recording of production (Good, Scrap, Reject and Finesse.)

The most common part activities that we find are:

- Automated production recording (and scrap/reject/finesse management)

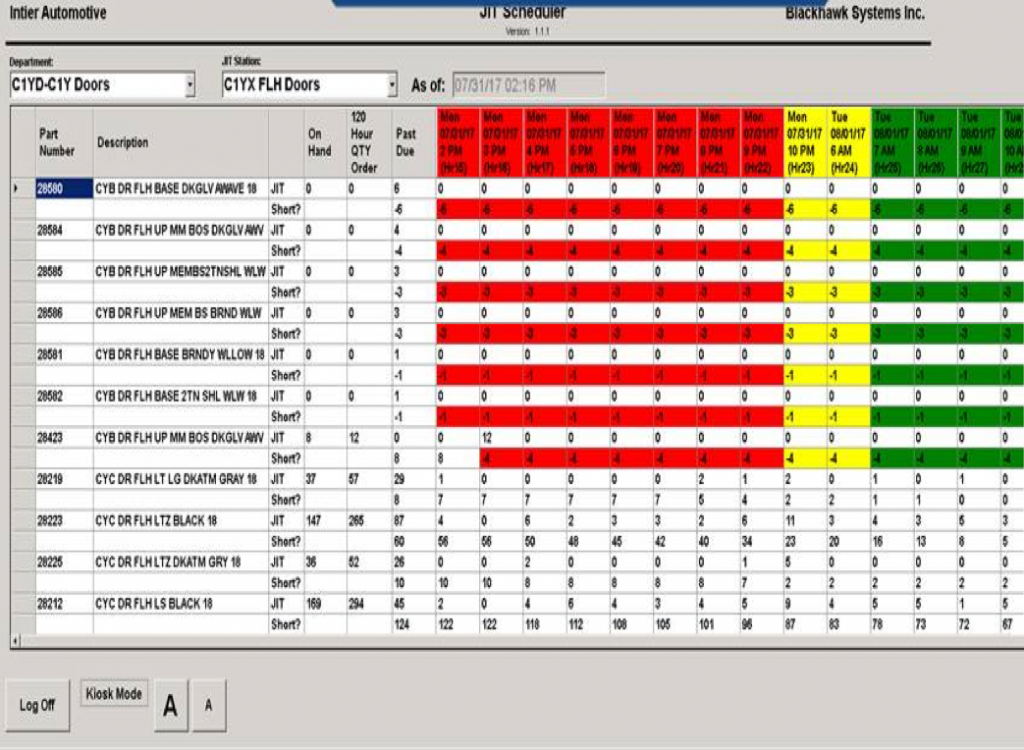

- FIFO inventory movement (at the part/container level)

- Aging (Part/Container obsolescence) engineering change management

- Part quality conformance validation when used in assembly (good part/correct part)

- Part production error-proofing at the operation level (must finish 0010 before 0020 etc.)

- Part recovery (from scrapped components)

- Additional Parts consumed (from rework to good)

- Correct part placement into the correctly labeled container

- Correct part/container on customer shipment

So from the initial printing of the part label, every activity of that part is easily and correctly error-proofed, recorded, and individually tracked.

For those workstations that need to produce part labels without a machine interface, the UI (user interface) should accomplish the printing of the part label through the simple use of a touchscreen-based pre-configured user interface.

General rules in the printing of the basis 2D part label…

- The serial number (license plate) used in the part label must be unique to the life of the part.

- The fixture (PLC code) generates the part label with an integrated part label print verification (and reprint with supervisor override.)

- The UI needs to allow the printing of the appropriate part label with an audit flag that the part was labeled outside of the automatic label print by the fixture.

- The UI needs to identify downtime event when the cycle time between the part label prints exceed two (2) times the normal part labeling cycle. (Most plants use the same UI to identify on-demand upstream/downstream downtime events as well as work instructions, quality alerts, etc.)

- The UI needs to automatically record production when the label is printed (or scanned.)

- The UI needs to enable the user to identify scrap/reject/finesse through the scanning of the part label.

We have found that the content of the part label enables a high level of error-proofing/part tracking.

- Our “Standard” 2D part label is a 3 character production line identifier, 3 character part code, the Model Year, Julian Date, Shift, and 5 digits sequential counter.

Examples:

- GM3:TS4:21:101:3:00011 – Production line “GM3” / Part code “TS4” / Model year “21” / julian date “101” / shift “3” / sequential counter “00011”

- MA1:001:21:001:1:09922 – Production line “MA1” / Part code “001” / Model year “21” / julian date “001” / shift “1” / sequential counter “09922”

- The production line identifier and the part code enable easy engineering part rev level changes without changing the PLC label printing code.

- The model year: Julian date: Shift enables production (good/reject/scrap/finesse) to be properly recorded for parts that need to be queued.

- The 5 digit serial number assures the uniqueness of the part label.

Note: A few OEMs have their own specifications for part labeling and you may end up dealing with serial numbers that are not unique. If this is an issue that you are dealing with, contact us and we can discuss the issues that will arise and how we work through them.

Note: For machine interfaces, Blackhawk uses a standard UI (touch screen pre-configured user interface,) that interacts with the fixture’s PLC through a Kepware driver.

Every good introduction leads to even more questions – so please drop me an email if you have any questions.